Electron Irradiation

Technical films often require special properties in order to be efficient, usable and durable in their application. Electron beam irradiation makes that possible which is often difficult or impossible to achieve through composition changes in film production: a change in film properties, e.g. in terms of heat restistance, hand-tearability, sterility or biodegradability.

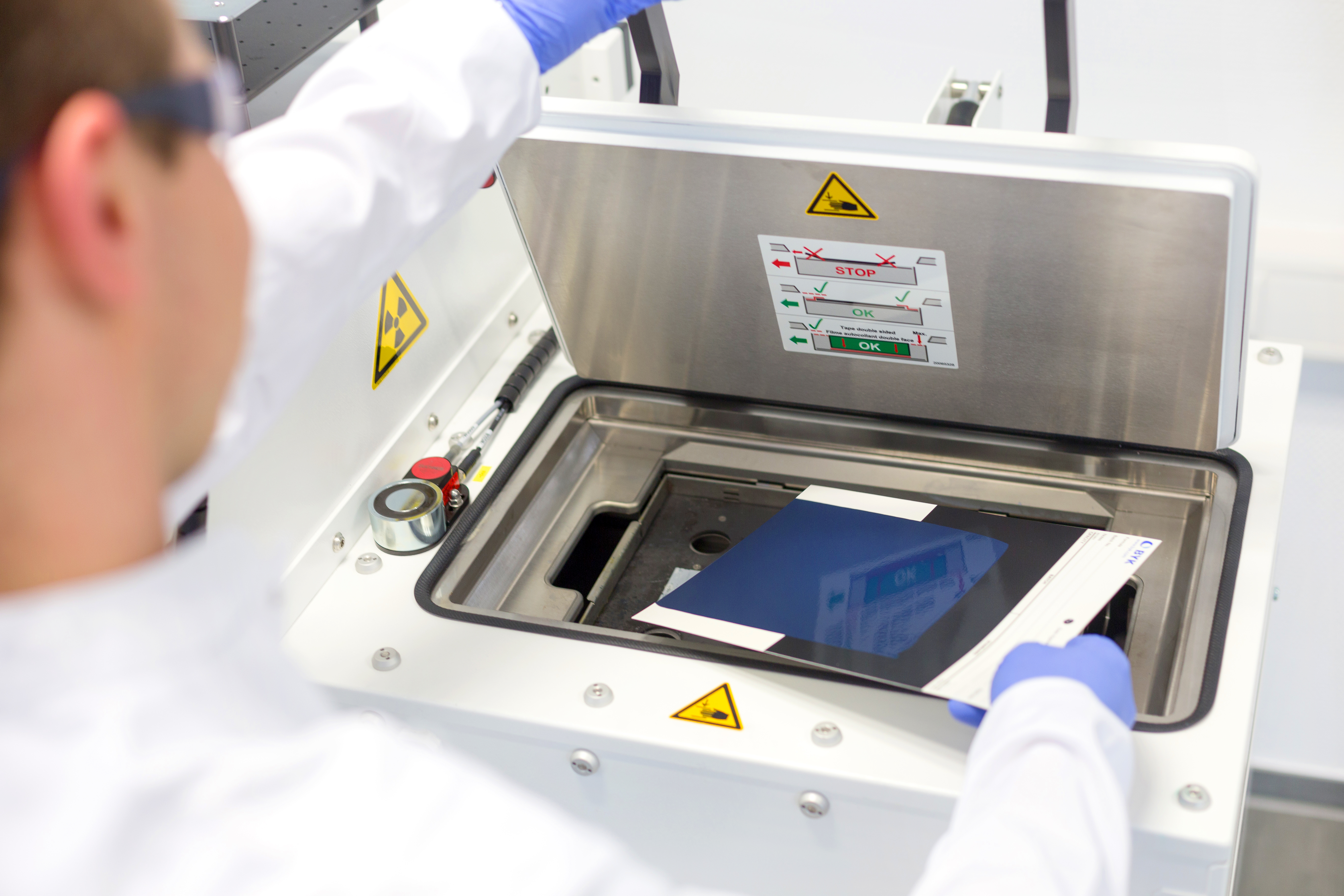

celotec´s production facility offers the best possibilities for treating plastic films with electron beams on an industrial scale.

Which plastics can be treated with electron beams?

- Polypropylen (PP)

- Fluorpolymers (PVF, PVDF)

- Ethylen copolymers (EVA, Surlyn)

- Nylon (PA6, PA6-6)

- Polyethylen (HDPE, LDPE, UHMW-PE)

- Polyacrylates

- Polyvinylchlorid (PVC)

- Synthesekautschuk (EPR, SBR)

- Natural rubber

- Polyurethane

- Silicon and nitrile rubber

- Polybuthylen terephtalates (PBT)

- EPDM

- Polybutadien

What property should your film have?

In our ESH system, accelerated electrons hit the molecules of the material and break their bonds. On this basis, chemical reactions are triggered that lead to changed properties. We will show you how to take advantage of processes such as electron beam cross-linking:

What is possible with celotec's highly functional E-Beam System?

The electron beam irradiator from celotec is part of a large roll-to-roll coating line. This system offers a wide range of options for the irradiation and coating of web-like media. Furthermore, the system has an optical web inspection system and offers the possibility of inline edge trimming. The coating section of the system, has UV units and excimer lamps in addition to the coating application unit.

A relaxing station, a web cleaning unit and a corona unit are installed for the pre-treatment of films. If required, films can be cut and wrapped crosswise and lenghtwise on a separate roll slitter.

In addition to irradiation, we offer you the best options for coating films and papers with radiation-curing coatings. Different coating systems in transparent and pigmented designs are available for a wide range of applications. In the same way, however, customised coatings can also be developed and precessed together to give films certain prperties or decorative character.

What is the process from laboratory sample to optimum film?

You would like to improve your plastic film by electron irradiation? No problem with celotec and celolab! This is because our excellently equipped surface laboratory also has an irradiation unit that can be used to carry out basic experiments.

We guide you through an efficient and transpartent process from your inquiry to the optimum product.